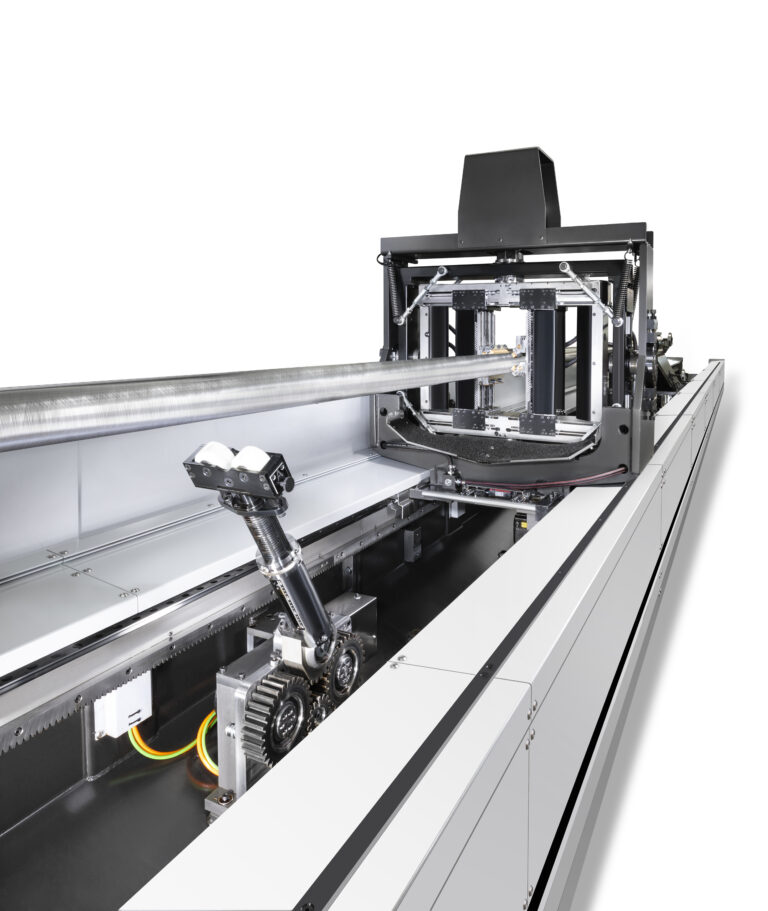

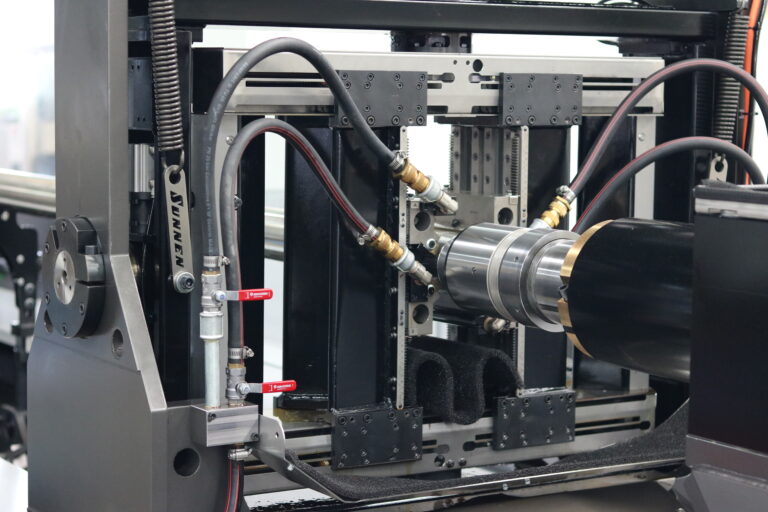

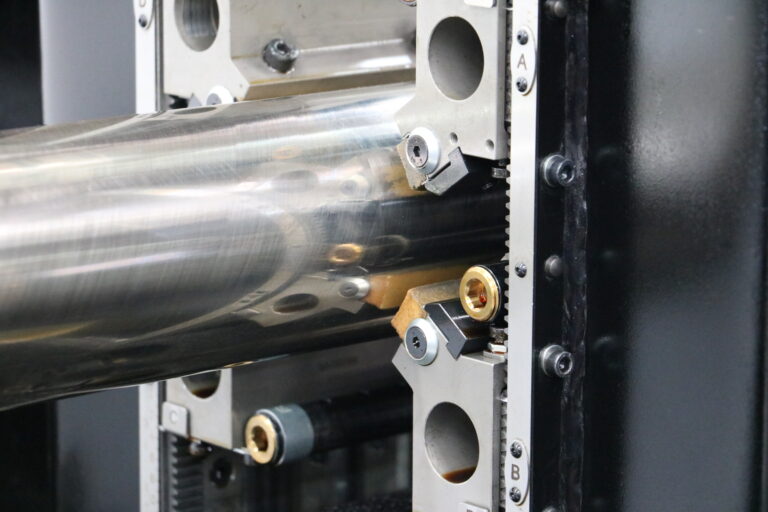

HES Serie

External Honing

The first External Honing Machine

Sunnen‘s first generation of external honing machines has been developed to meet the continuously increasing demands of the industry. Workpieces in the offshore, energy production and aviation sectors are exposed to extreme environments. Therefore electroplated hardchrome or plasma-spray coated surfaces are in operation. The new HES machine cuts nearly all advanced materials without trouble, next to mild steel. Sunnen built an outstanding control with maximum comfort and safety as a result of over 30 years of experience.

Sunnen provides the major advantages for your future production.

Details

Specifications and advantages

- Spindle motor

15 kW - Diameter range

50 – 450 mm - Stroke length

500 – 15‘000 mm

- Large diameter range

- Automatic correction of roundness and parallelity

- Operator-friendly, Windows ®-based monitoring system

- Tool overload protection

- Easy operation with industrial touch screen

- Programmable dimension monitoring

Tube Hones

Solutions for a large diameter range.

Performance & Benefits

HTC-x121

- Short setup and changeover time

- Automatic bore geometry correction

- Program memory for over 900 setups

- 100% process control with tool overload protection

- Operator-friendly Windows®-based monitoring system

HTB Series

- Automatic bore geometry correction

- Fast setup

- Simple operation

- Excellent for repair & job-shop production

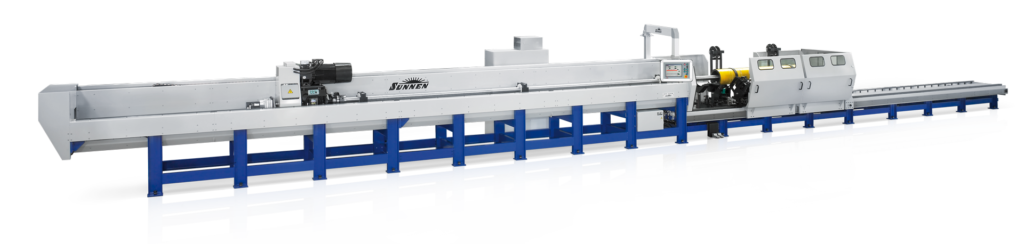

HTH Series

- Automatic bore geometry correction

- Fast setup

- Simple operation

- Excellent for production

HTC Series

- Large diameter range

- Automatic bore geometry correction

- Operator-friendly Windows®-based monitoring system

- Fast setup

- Excellent for production

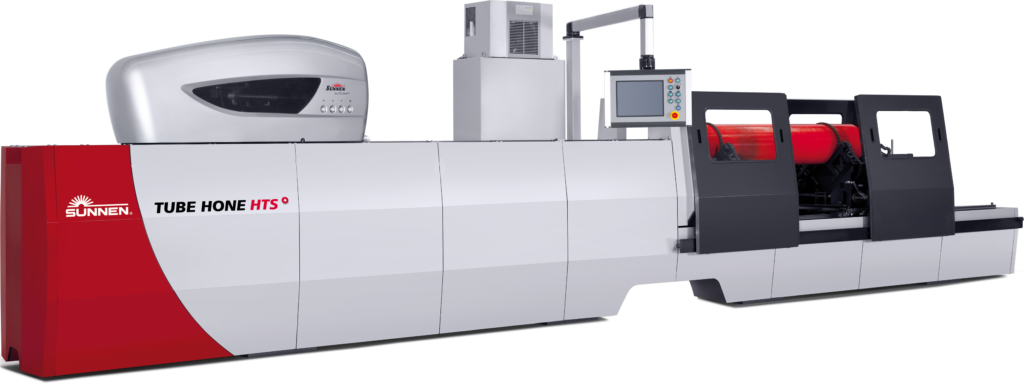

HTS Series

- Large diameter range

- Automatic bore geometry correction

- Operator-friendly Windows®-based monitoring system

- Tool overload protection

- Easy operation with industrial touch screen

- Programmable dimension monitoring

HTD Series

- Large diameter range

- Automatic bore geometry correction

- Operator-friendly Windows®-based monitoring system

- Tool overload protection

- Easy operation with industrial touch screen

- Programmable dimension monitoring

- High stock removal up to 2’500 cm3/h

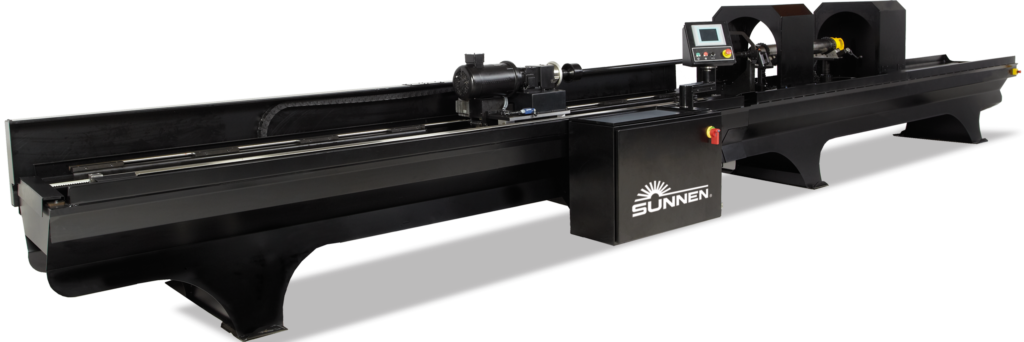

HES Serie

- Large diameter range

- Automatic correction of roundness and parallelity

- Operator-friendly, Windows ®-based monitoring system

- Tool overload protection

- Easy operation with industrial touch screen

- Programmable dimension monitoring

|

|

|

|

|

|

|